The spiral freezing machine is an efficient and compact continuous freezing equipment. Its core feature is the use of a spiral conveying structure to extend the freezing path of the materials, enabling rapid and uniform cooling within a limited space. It is widely used in food processing (such as quick-freezing of fruits and vegetables, pastries, meat, seafood, etc.) and the catering supply chain, etc. The following is an analysis of its key features, working principle, advantages, and application scenarios:

1. Core Structure and Working Principle

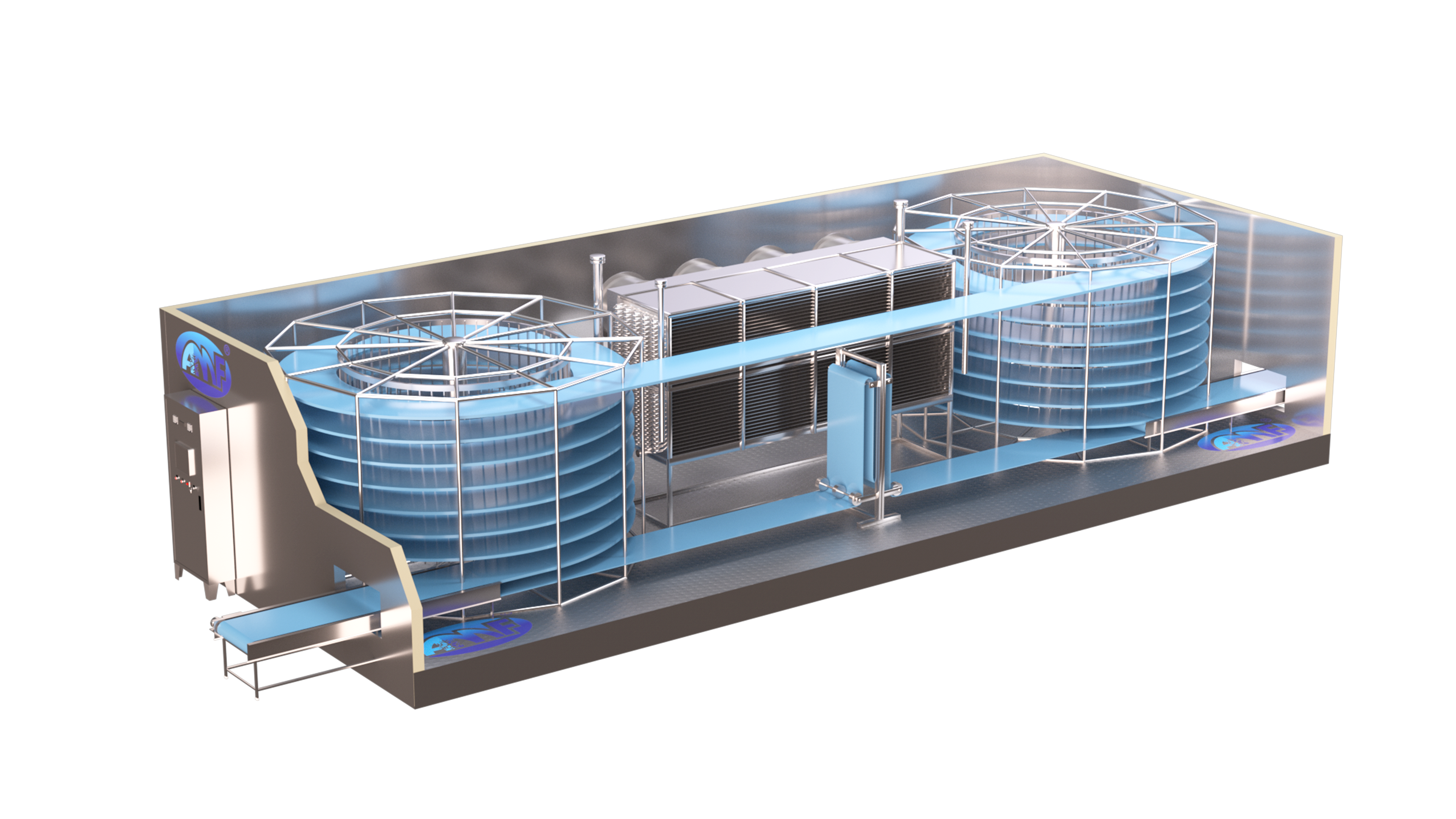

The design of the spiral freezing machine is centered around “spiral conveying + forced convection cooling”. The main components include:

Spiral Conveying System:

Composed of a central column and multiple layers of conveyor belts (or mesh belts), the material moves along the conveyor belts in a spiral trajectory, moving upwards or downwards. The path length is much longer than that of a linear freezing machine (with the same floor space, the freezing path can be extended by 3-10 times).

Refrigeration System:

Usually, it adopts air-cooled evaporators (or liquid nitrogen/CO₂ assisted refrigeration). The fan forces cold air to blow onto the material layer of the conveyor belt, creating vertical or horizontal convection to ensure uniform cold distribution.

Insulation Box:

The entire structure uses polyurethane foam insulation layer to reduce heat loss and maintain a low-temperature environment inside the box (common freezing temperatures: -18℃ to -40℃, adjustable according to the material).

Feed/Discharge Device:

Automatic feeding (such as belt machine connected to the production line) and discharge mechanism, enabling continuous operation.

Work Flow:

The material enters the spiral conveyor belt from the feed inlet → moves along the conveyor belt in a spiral upward/downward motion, passing through multiple refrigeration areas → cold air continuously penetrates the gaps between the material, quickly removing heat → finally exits the discharge outlet with the frozen material (freezing time usually 5-60 minutes, adjusted according to material properties and production capacity).

II. Key Advantages

Compared to traditional linear freezing machines or refrigeration cabinets, the core competitiveness of the spiral freezing machine lies in:

High space utilization:

The spiral structure compresses the “long freezing path” into a vertical/compact circular space, with a floor area only 1/3 to 1/5 of that of a linear machine, suitable for scenarios with limited workshop space.

High and uniform freezing efficiency:

The combination of forced convection and long path design avoids uneven freezing caused by material stacking; the wind speed and temperature can be adjusted as needed, suitable for different materials (such as leafy vegetables require low wind speed to prevent damage, meat pieces require high wind speed to accelerate freezing).

Strong continuous production capacity:

From feeding to discharging, it operates automatically, with stable production capacity (single machine capacity can reach 100-5000 kg/h), suitable for large-scale industrial production.

Better energy efficiency:

The insulation box reduces heat loss and shortens the ineffective stay time of materials in the box, reducing energy consumption (about 30% to 50% lower than traditional refrigeration cabinets).

Flexibility and compatibility:

It can be paired with different widths of conveyor belts (suitable for granular, block, and sheet materials), and some models support “double spiral” or “multi-layer spiral”, further enhancing production capacity.

III. Main Types

Based on structure and refrigeration method, it can be classified as:

By spiral direction:

Single spiral: Simple structure, suitable for small to medium production capacity;

Double spiral: Two layers rotating in opposite directions, improving space utilization and production capacity, suitable for large-scale production.

By refrigeration medium:

Mechanical compression refrigeration type (mainstream): Uses Freon or environmentally friendly refrigerants (such as R404A, R507), lower cost;

Liquid nitrogen/CO₂ freezing type: Directly sprays or jets liquid nitrogen (-196℃) or liquid CO₂ (-78℃) for refrigeration, freezing speed is extremely fast (from a few minutes to over 10 minutes), suitable for high-end ingredients (such as sushi, premium seafood), but has higher operating costs.

By conveyor belt material:

Mesh belt type: Good air permeability, suitable for granular and small block materials (such as dumplings, blueberries);

Plate/chain plate type: Strong bearing capacity, suitable for large block materials (such as whole chicken, steak).

IV. Typical Application Scenarios

The spiral freezing machine is the core equipment in the freezing process of the food industry, commonly used in:

Fruit and vegetable processing: Freezing strawberries, peas, broccoli, spinach, etc. (maintaining color and nutrition);

Cereal and flour products: Freezing buns, dumplings, tamales, spring rolls, etc. (preventing sticking and cracking);

Meat, poultry, seafood: Freezing chicken wings, fish pieces, shrimp, steak, etc. (locking moisture and texture);

Prepared foods: Freezing ready-made packages, sausages, fried chicken semi-finished products, etc. (meeting the rapid serving requirements of restaurant chains).

V. Selection and Maintenance Key Points

Selection key factors:

Production capacity demand: Select the model corresponding to the required production capacity based on the size of the production line (e.g., 500kg/h vs 5000kg/h);

Material characteristics: Consider the size, shape, and heat sensitivity of the materials (e.g., ice cream requires an ultra-low temperature model);

Workshop space: Measure the available area and match the spiral diameter and height (common spiral diameters range from 1 to 5 meters);

Energy consumption budget: Mechanical refrigeration models are suitable for long-term large-scale production, while liquid nitrogen models are suitable for small-batch high-end products.

Daily maintenance:

Regularly clean the conveyor belt and evaporator (to prevent ice accumulation that may affect the cooling efficiency);

Check the tension of the fan belt and the refrigerant pressure;

Calibrate the temperature sensor to ensure precise freezing temperature.

VI. Industry Trends

As the food industry places greater emphasis on “freshness” and “production efficiency”, spiral freezing machines are evolving towards being more intelligent, energy-efficient, and customizable:

Intelligent Control: Equipped with PLC or IoT system, it can monitor temperature, wind speed and production capacity in real time, and automatically alerts in case of abnormalities;

Customized Models: Designed for special materials (such as soft fruits and fragile pastries), it features low wind speed and gentle belt transportation for dedicated spiral freezing machines.

In summary, the spiral freezing machine, with its characteristics of “small space, high efficiency, and continuous operation”, has become one of the preferred equipment for modern food rapid freezing processing. It is particularly indispensable in large-scale production and scenarios with limited space.

Post time: Feb-05-2026