There are mainly two types of IQF freezers used in the process of individually quick freezing food products: spiral freezers and tunnel freezers. Both types of freezers use a continuous movement of product through a freezing enclosure to quickly freeze it.

Spiral freezer — Spiral freezers can be either mechanical or cryogenic. The product to be frozen is moved on a spiral conveyor inside an insulated freezing enclosure.

Tunnel freezer—Tunnel freezers can be either mechanical or cryogenic. The product to be frozen is moved on a linear conveyor through an insulated freezing tunnel.

Cryogenic freezing methods are usually cheaper in the beginning but have higher long term operating cost due to continuous consumption of cryogenic gas like liquid nitrogen. It is suitable for smaller operations, new product development, or seasonal production.

Mechanical freezing is a mechanical refrigeration cycle that uses refrigerants like ammonia or carbon dioxide to freeze products. It is more suitable for long term, steady production of high volumes. Our spiral and tunnel freezers are all designed by mechanical freezing.

The difference between a spiral and tunnel freezer lies mainly in footprint and belt structure. Here are the differences between the tunnel freezers and the spiral freezers:

1. Design and operation

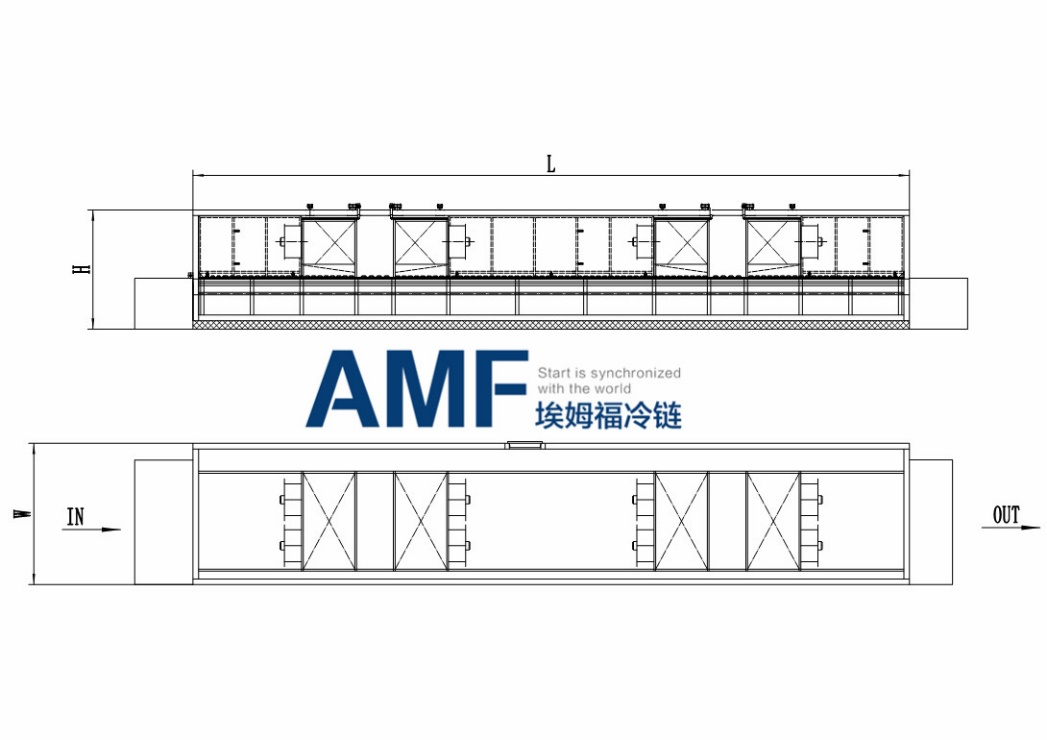

Tunnel freezers are designed as long straight tunnels that transport the products on a conveyor belt through the freezer. The product is exposed to a high-velocity stream of cold air, typically -35°C to -45°C, which quickly freezes the product.

Tunnel Freezer Schematic Diagram

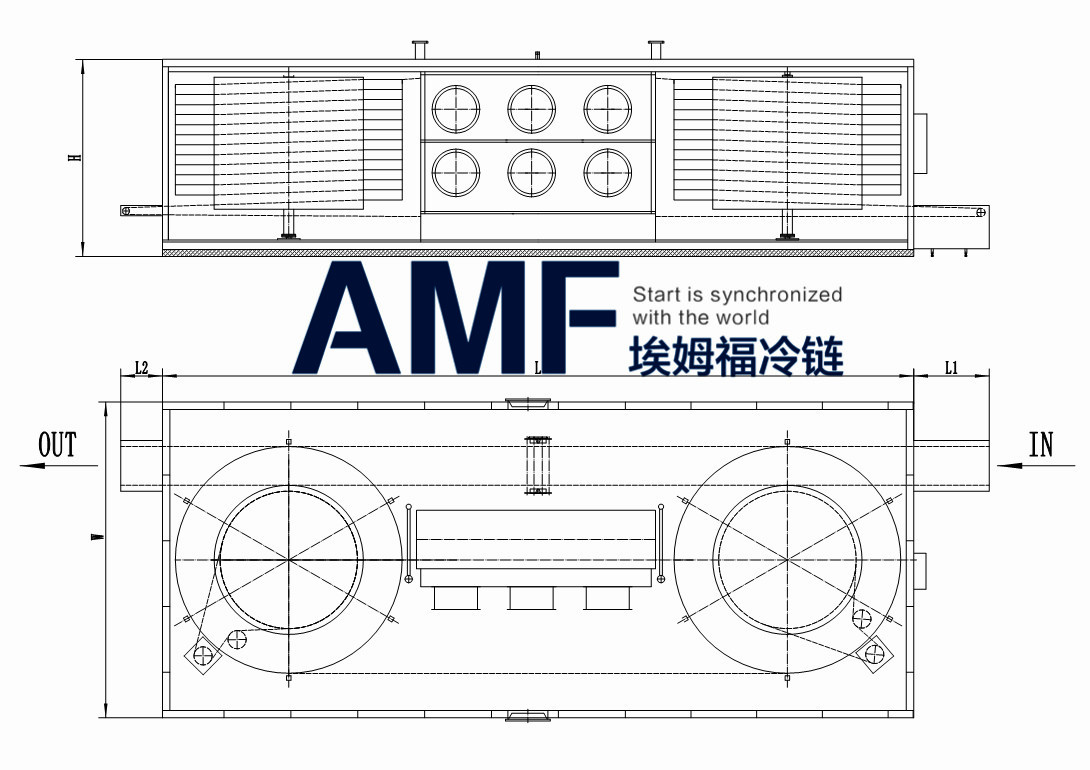

On the other hand, spiral freezers are designed with a conveyor belt that moves in a spiral pattern. The product is exposed to a lower-velocity stream of cold air, typically -35°C to -40°C, which gradually cools the product as it moves through the spiral.

Spiral Freezer Schematic Diagram

2. Product type

The type of product you need to freeze is a critical factor. Some products may require more space to freeze evenly, while others may require rapid freezing to maintain quality.

3. Freezing capacity

Tunnel freezers are better suited for high-capacity production lines that require rapid freezing of product in a short period of time. They are typically used for freezing large food items, such as pizzas, or for freezing large quantities of small items, such as vegetables or fruits.

Spiral freezers are better suited for freezing production lines that require more gentle handling of the product. They are typically used for freezing delicate food items, such as seafood or bakery products, or for freezing products that need to be individually quick frozen (IQF). If you have a high volume of product to freeze, a spiral freezer also is more efficient than a tunnel freezer.

4. Energy efficiency

Tunnel freezers require more energy to operate due to the higher velocity of air used to rapidly freeze the product. This can lead to higher energy costs and a greater environmental impact.

Spiral freezers, on the other hand, use a lower velocity of air to gradually cool the product, which requires less energy and is more energy-efficient overall.

5. Available space

If space is limited, a spiral freezer with smaller footprint may be a better option.

6. Maintenance

Tunnel freezers are relatively easier to maintain due to their simple design. The conveyor belt can be easily accessed for cleaning and maintenance, and any broken components can be easily replaced.

Spiral freezers are more complex to maintain due to their spiral design.

The two different kinds if IQF freezers have different strengths and weaknesses, and which type to choose will depend on the specific needs of the production line.

Ultimately, the choice between a tunnel freezer and a spiral freezer will depend on your specific needs and requirements. It is important to thoroughly evaluate your needs and consult with a freezer expert to determine which option is best for your application.

Contact us now for free customized design of your food freezing line.

WhatsApp/wechat: +8615370957718; email: kisa@emfordfreezer.com

Post time: Mar-13-2023