In modern food production, the ability to freeze food quickly and efficiently is of paramount importance. One technology that has emerged to meet this demand is the spiral freezer, a type of freezer that employs a unique working principle to rapidly freeze food products. In this essay, we will explore the working principle of the spiral freezer and its advantages in food production.

The spiral freezer is a type of continuous freezer, which means that it is designed to freeze food products continuously as they pass through the freezer. The basic design of the spiral freezer is relatively simple: food products are placed on a conveyor belt that is wrapped in a spiral shape around a cylindrical drum. As the conveyor belt moves through the spiral, the food products are exposed to a stream of cold air that freezes them rapidly.

The working principle of the spiral freezer is based on the concept of convective heat transfer. When the cold air is blown over the food products, heat is transferred from the products to the air. This causes the temperature of the food products to drop rapidly, resulting in their freezing.

One of the key advantages of the spiral freezer is its high freezing rate. Because the food products are continuously exposed to the cold air as they pass through the spiral, they are frozen much more quickly than in a traditional batch freezer. This rapid freezing rate is important for maintaining the quality of the food products, as it reduces the formation of ice crystals that can damage the product's texture and flavor.

Another advantage of the spiral freezer is its efficiency. Because it is a continuous freezer, it can handle a large volume of food products in a relatively small amount of space. Additionally, the spiral design of the freezer means that it can be easily integrated into a production line, allowing food products to be frozen quickly and efficiently as they move through the production process.

In conclusion, the spiral freezer is a key technology in modern food production, offering a unique working principle that allows food products to be frozen quickly and efficiently. By leveraging the principles of convective heat transfer, the spiral freezer provides high freezing rates and efficiency, making it an essential tool for ensuring the quality and safety of food products.

Single spiral freezers and double spiral freezers are both types of industrial freezers used to rapidly freeze food products for storage and transportation. However, they differ in their design and capacity.

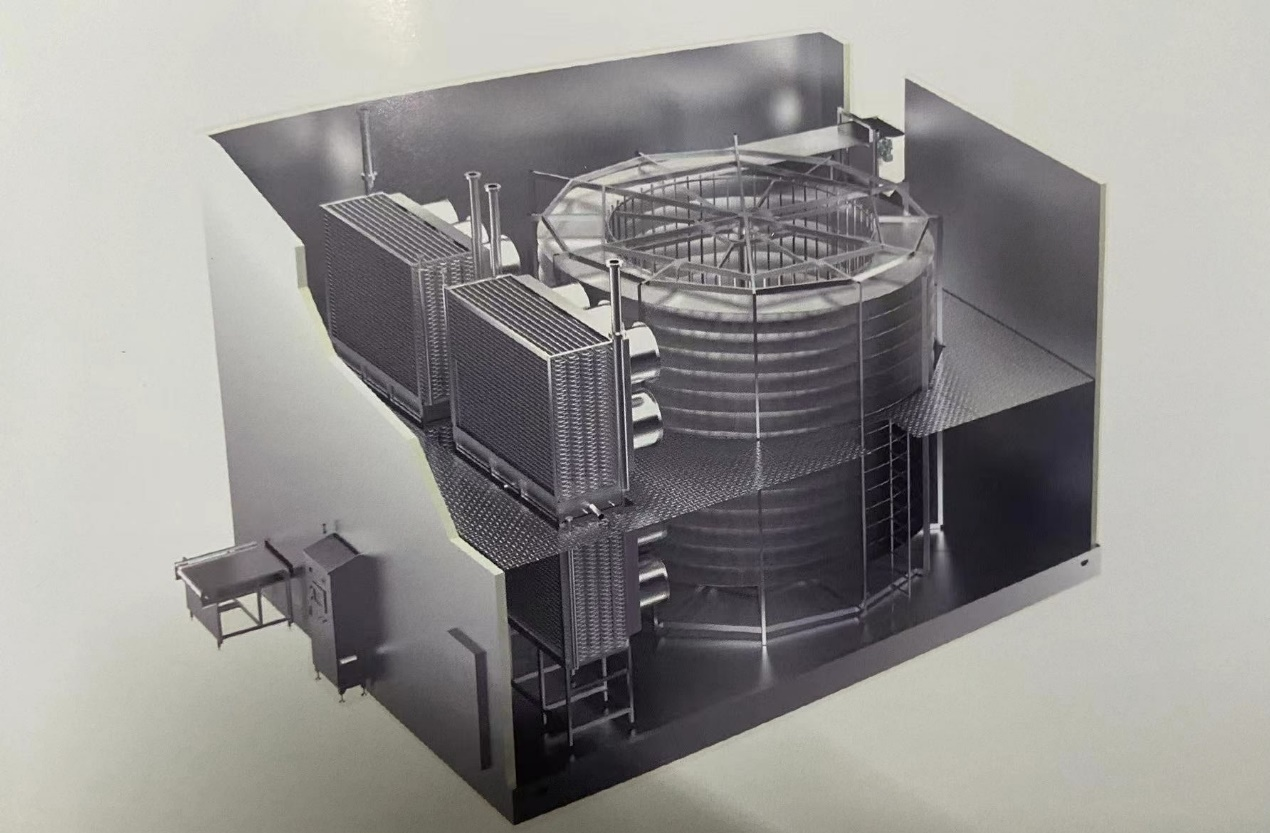

Single spiral freezers are typically used for smaller-scale production operations, and are best suited for freezing relatively flat food products such as baked goods, vegetables, and small meat products.

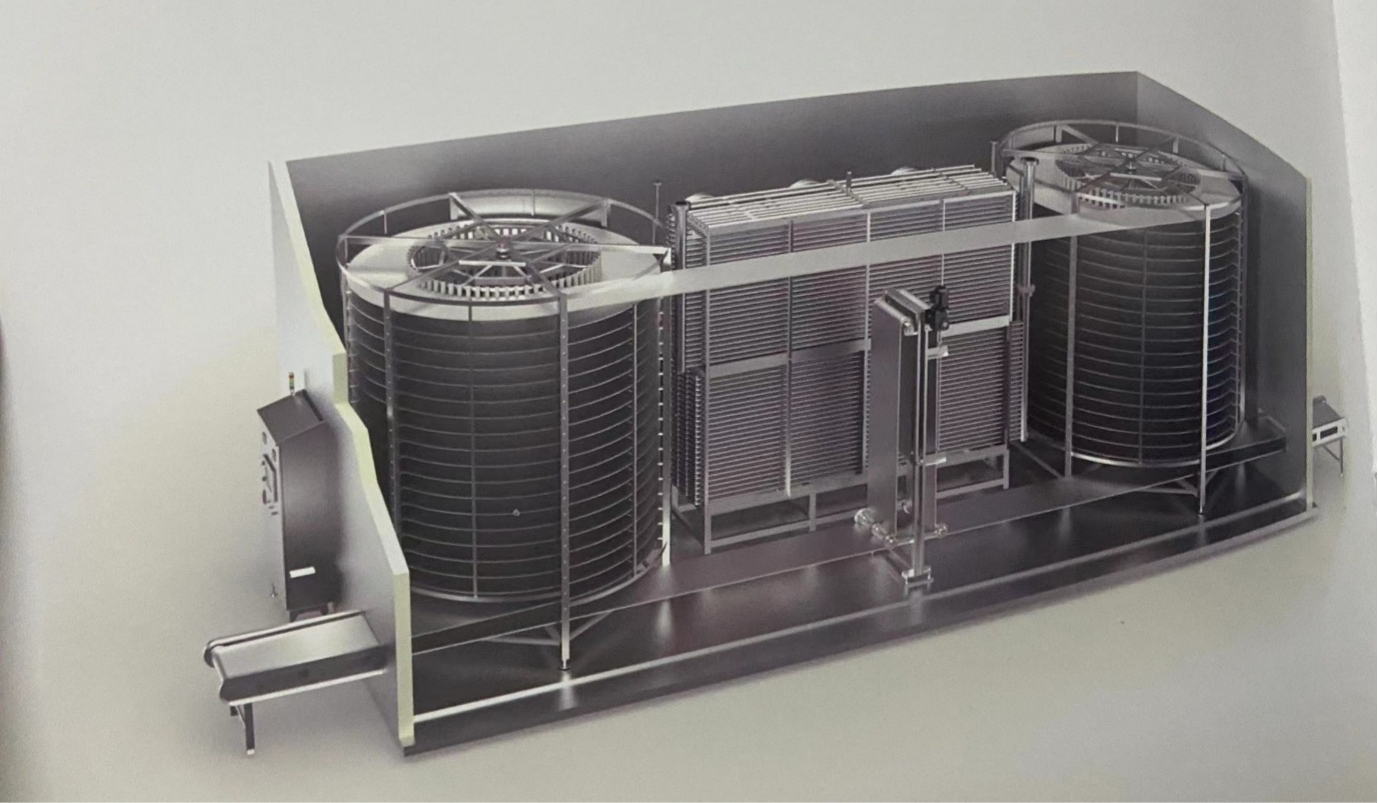

On the other hand, double spiral freezers are designed for larger-scale production operations, and are best suited for freezing larger food products such as meat cuts and seafood. The double spiral freezer has a larger capacity than a single spiral freezer, and can typically freeze food products at a faster rate due to its greater surface area and increased air flow.

Double Spiral Freezer Schematic Diagram

Single Spiral Freezer Schematic Diagram

Post time: Feb-27-2023